11 April 2022

The interior window sill is a small element that plays an important role for every building. There are many different solutions available on the market, so the choice can be problematic for many people. Before making a decision, it is worth exploring all the options carefully and choosing the ideal solution for your needs. In this article we have gathered the most relevant issues for you.

What are the functions of external window sills?

Although it may seem inconspicuous, the exterior window sill plays an important visual role. Exterior window sills emphasise the character of the building, therefore they must match both the colour scheme and the type of façade and window joinery.

The visual aspect is undoubtedly important for many of us, but special attention should be paid to the functional aspect. The window sill prevents rainwater from getting under the window frame and onto the façade, protecting it against damp patches and mould. It is mounted at a gentle slant so that the water flows freely onto the ground. A well-chosen window sill protects the property owner from unnecessary expenses associated with damage to joinery or dampness in the building.

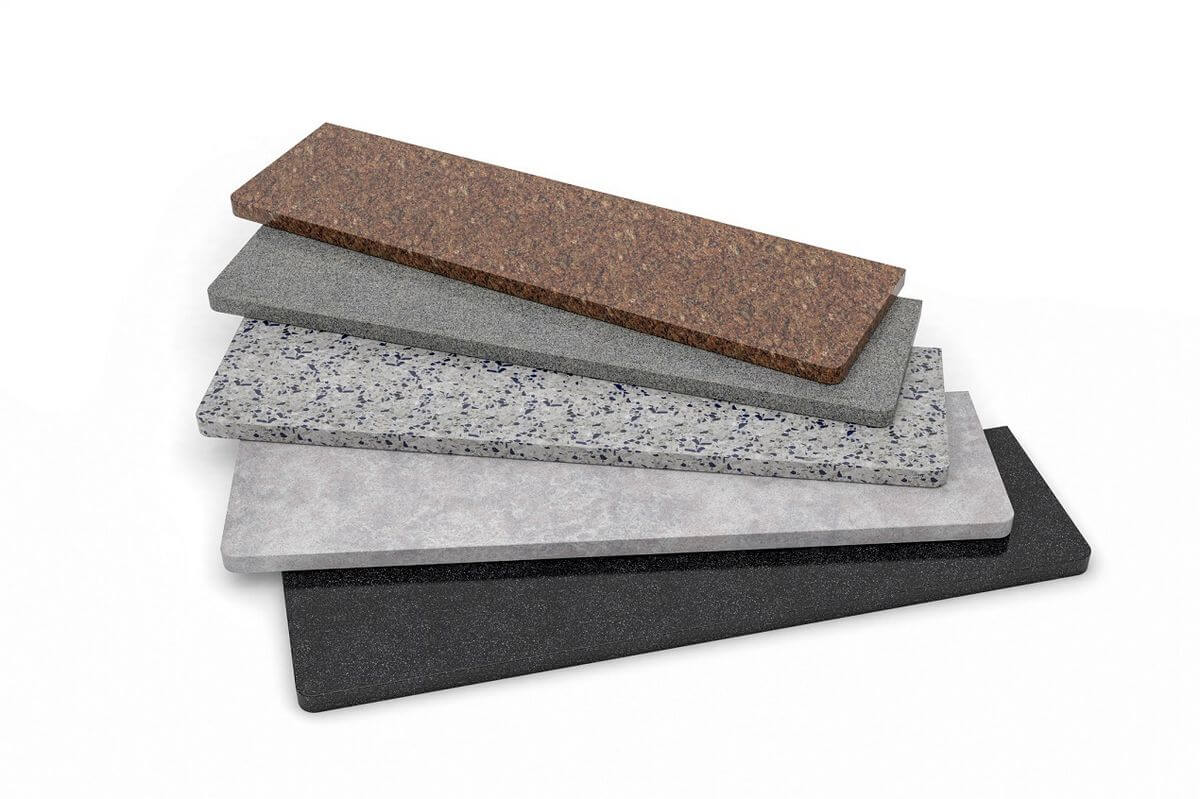

Types of external window sills

The answer to the question of which exterior window sill to choose is complicated by the fact that there are many solutions available on the market. There is also no perfect solution, as individual visual preferences or financial possibilities must be taken into account at the selection stage. The available types of external window sills differ in terms of durability, resistance to damage, colouring options, maintenance methods and ultimately price.

We divide external window sills according to the material used in their manufacture.

Steel window sills.

Steel window sills, or more precisely - made of galvanised steel - are the most popular and economical solution. In order to increase their resistance and aesthetics, sheet metal is powder-coated with acrylic or polyester varnishes. The advantage is the low price and the wide range of sizes available. They are manufactured in sheets 9-40cm wide and up to 6m long. However, metal is quite susceptible to scratches. Its service life can be extended by regular care and maintenance - for up to 30 years. When looking for a drawback, it is worth mentioning the noise caused by raindrops crashing against the sheet metal.

Aluminium window sills.

Aluminium window sills resemble the steel ones in some respects, but they have higher technical parameters. They are more rigid than their predecessors and resistant to corrosion. In addition, the protection of the surface with varnish makes them maintenance-free. Their advantage is also higher resistance to moisture, UV rays or mechanical damage.

Another advantage is that these window sills are sold with matching accessories. A wide range of colours is also important, as they are powder-coated in the permitted RAL colour and can have smooth or embossed surfaces.

The disadvantage of the solution is the expansion of the material used for production under the influence of heat. It is therefore recommended that an expansion gap is maintained at the ends of the sills and around the fixing bolts. This solution may also not be suitable if you are annoyed by the noise, as in this case you will also clearly hear the raindrops crashing against the aluminium surface.

Plastic (PVC) window sills

Under the term PVC window sills we will find products made of foamed or hard PVC, covered with laminate, i.e. the material used for production of the most popular window profiles. In contrast to their predecessors, they have the advantage of great supressiion of the noise of falling raindrops. Plastic window sills can be found in many colours and veneers, including those imitating wood, so it is easy to match them to the façade or woodwork. They are also resistant to corrosion or acid rain and are easy to keep clean. Unfortunately, their biggest disadvantage is their lower durability. It will therefore not be a good solution for people who plan to install window sills for many years.

Ceramic and clinker window sills

Clinker and ceramic window sills are another option available. They can be made from bricks, shaped pieces or clinker tiles, so they come in different thickness sizes and formats. They are an extremely visually attractive solution, which is why they are chosen by those looking for unconventional finishing options. The colours of clinker window sills are usually shades of red, yellow, brown and grey; white or black ceramic elements are also available on request. Their advantage is also high resistance to weather conditions or extreme frost. Unfortunately, they are not as resistant to mechanical damage, and accidental damage with a durable object can result in damage. A disadvantage for many may also be the greater weight of this type of sill. They are also a relatively expensive option.

Stone window sills

Natural stone is a solution that works well in a variety of settings. The most popular are marble and granite window sills, which are characterised by high visual advantages resulting from the interesting and unique structure of the stone. Their colours vary - depending on the stone used, we can choose from white, red, green, blue, grey, beige or black window sills. Their surface can be polished, matted, sanded, flaked or hammered.Stone window sills are characterised by durability and resistance to weather conditions as well as abrasion and scratches. They are also easy to clean and require no maintenance. They can be enjoyed by property owners for many years. However, we must point out that this is the most expensive of the solutions presented, which for some may prove to be a disadvantage.

Installation of external window sills

Properly prepared and professionally carried out installation is the basis for ensuring that the exterior window sill maintains its properties. Incorrect installation can damage the thermal insulation layer of the window and create thermal bridges that cause heat to escape from the building and generate unnecessary additional costs.

In theory, external window sills can be installed at any time during construction. However, most contractors suggest that this is done in the period between window installation and plastering. This will result in a tighter connection between the window sill and the frame and wall, and will also make it easier to create an aesthetically pleasing façade.

Most importnat rules of external window sill installation

Rule 1

External window sills should be made with a slope of approximately five degrees towards the outside. This will allow rainwater to run off freely from its surface.

Rule 2

The second important rule is to install the window sill in such a way that its outer edge is extended beyond the face of the wall by at least 5 cm. Then the water flowing down the sill will be a few centimetres from from the wall.

Rule 3

When installing, make sure not to cover the holes placed in the lower profile of the window frame. This is important as the outlets are responsible for the removal of moisture and water vapour. Covering them by the window sill would prevent the window structure from regulating moisture.

Rule 4

The fourth rule is related to the installation of window sills in the wall. Pay attention not to plaster the edges of the sill. This is a big mistake, as the material from which the window sill is made can change under the influence of temperature and by pushing against the wall cause it to crack. It must be able to change its length thermally by sealing the contact points with permanently plastic materials.

It is also worth mentioning that it is not recommended to install heavy external window sills in two-layer walls, as it is difficult to support them directly on the insulation. This problem can be eliminated by using additional supports. It is advisable to leave the execution of such installation to the experts.

Rule 5

Metal window sills (steel and aluminium) should be adequately protected against strong gusts of wind. Sound insulation is also important - a special damping pad is glued on for this purpose.